Line Boring

At Hoffman Manufacturing, Inc., we are a go-to design and build manufacturer for customers in many different industries. We offer line boring services, among many other services, to help you meet all of your custom equipment needs.

At Hoffman Manufacturing, Inc., we are a go-to design and build manufacturer for customers in many different industries. We offer line boring services, among many other services, to help you meet all of your custom equipment needs.

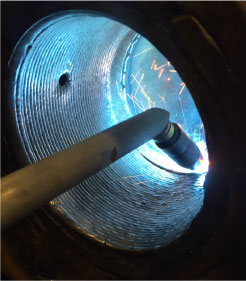

Line boring is the process of enlarging a hole that has already been drilled. You could consider it the internal diameter counterpart to turning, which involves cutting external diameters. Line boring is carried out using one or more cutting tools held within a boring head. The process achieves greater accuracy in cutting internal diameters, and it can even be used to create tapered holes.

Line boring is an especially valuable service in the mining industry. Line boring can be used to return old or worn parts back to manufacturer specifications, in compliance with specified repair procedures. Worn pin bores, tunnel bores, axle pivots, and bearing housings are all examples of problems that can be addressed with line boring. With every line boring job you can rest assured that you will receive extremely accurate measurements along with a highly professional finish. We are also highly experienced and can complete any job with minimal downtime.

We offer line boring and bore welding along with many other custom industrial solutions. Our experienced staff will work with you to design and build custom solutions from start to finish. We also perform onsite evaluations as needed to offer you the best possible solution. Whether you are looking to repair heavy equipment on-site or have your industrial equipment customized at our site, contact us today to have us create the perfect custom solution for you.